POLYSINT grey kg.20

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

POLYSINT is a pigmented waterproofing protective elastomeric liquid membrane created by an aqueous dispersion of modified acrylic copolymers. Manufac... See more

POLYSINT is a pigmented waterproofing protective elastomeric liquid membrane created by an aqueous dispersion of modified acrylic copolymers.

Manufacturer country - Italy

See less

- Specifications

- Advantages

- Application area

POLYSINT is a ready product and must be stirred to an even, fluid consistency before being applied, using a brush, roller or airless spray gun.

Before applying POLYSINT, make sure you remove any parts that are loose, crumbling away or unsound, along with any paint, rust, dust or form oils; surfaces must be thoroughly

cleaned, sound and dry.

You are advised against applying POLYSINT if it is about to rain, or if there is a chance of dew, fog or frost as the product could get washed off or not adhere to the treated surface.

Avoid temperature extremes during the film's application and drying time.

You must be sure that there will be optimal installation conditions for at least 24 hours prior to and following application.

Being a water-based product, POLYSINT is affected by freezing temperatures and must be applied with ambient temperatures in the +5 to +35 °C range.

POLYSINT is applied in 2 coats: the second coat must be applied at least 24 hours after the first coat has been allowed to dry.

In the event you wish to improve the product's mechanical strength, or where it is not being applied straight on top of prefabricated bitumen membranes, we recommend applying

POLIESTERE 60 reinforcement.

To apply the reinforcement correctly, embed POLIESTERE 60 in the first coat while the material is still wet, applying suitable pressure as you roll over it so that it is incorporated

into the coating.

The average consumption rate varies depending on the substrate and desired thickness. Whatever the case, the average consumption rate for the 2 coats without reinforcement

is 1-1,5 kg/m2; while with reinforcement, it is 1,5-2 kg/m2.

The substrate should not be too hot as this accelerates the film-forming process, running the risk of the product not adhering properly and losing cohesion.

Do not apply to bitumen membranes that have just been installed as the natural small amount of migration of oils in the compound might mean the product fails to adhere

perfectly.

We recommend waiting at least 6 months when dealing with torched-on bitumen membranes or other bituminous materials, and 3 months on cold-applied bituminous materials;

in all cases, give the surfaces to be treated time to oxidize.

POLYSINT reduces carbonation of concrete. After drying, it forms a strong, elastic membrane that adheres perfectly to the surface, like concrete and polymer-bitumen membranes.

POLYSINT is used to coat and waterproof concrete structures, fibre-cement, wood or polymer distilled bitumen membranes.

It is suitable for protecting concrete substrates with a pitch greater than 3% (to avoid ponding).

It is particularly suitable for protecting surfaces waterproofed with bitumen membranes surfaced with talc, sand or slate chippings.

The product is not recommended for application on surfaces showing clear signs of cracking, distress or failure of any kind, on which it would not be successful in remediating

the waterproofing.

PACKAGING

1 kg, 5 kg, 10 kg and 20 kg containers.

POLYSINT is used for coating concrete structures, fiber cement, wood or polymer-bitumen membranes. Suitable for protecting concrete foundations with a slope greater than 3%. Particularly suitable for protecting surfaces isolated with bitumen membranes, covered with pieces of talc or sand.

Products offered

Planitop Rasa e Ripara - fibre cement for levelling concrete surfaces and repair work

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

Hydrostekloizol TPP 3.5 (1*10m2) )

- category: Waterproofing / Roll waterproofing

- Brands: KRZ

Synthetic rubber waterproofing Aquaflex Roof HR / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

Foamjet T two-component injection solution A+B 20+24 kg

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

FOX PURMAX FS601 WHITE 25

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

FOX ULTRASEAL-UV FS485 white SET 30kg

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

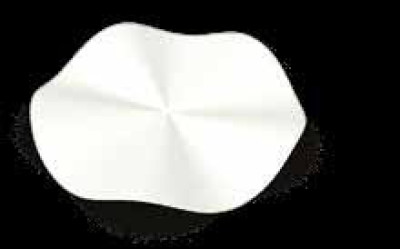

FOX BASEMOR FC205 GRAY 25 kg - mortar

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

PVC membrane MAPEPLAN M 15 BROFF T1/T3 2.10x20

- category: Waterproofing / Membranes

- Brands: MAPEI

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

WEBER DRY SS 10 20 KG (waterproofing powder)

- category: Coating waterproofing

- Brands: WEBER

Two-component polyurethane waterproofing COMPOSIT CRYSTAL (set)- 6.74KG

- category: Coating waterproofing

Primer bituminous (Primer) Profimast (5 l / 4.5 kg)

- category: Coating waterproofing

Polyurethane waterproofing Purtop Easy / 25 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

KEEP DRY 18KG BIANCO OSTUNI - Liquid Extra Strength Membrane

- category: Coating waterproofing

- Brands: ICOBIT

FOX CERAFLEX FX114 GREY 25 kg - High-strength cement adhesive

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

Planitop Rasa e Ripara - fibre cement for levelling concrete surfaces and repair work

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

Hydrostekloizol TPP 3.5 (1*10m2) )

- category: Waterproofing / Roll waterproofing

- Brands: KRZ

Synthetic rubber waterproofing Aquaflex Roof HR / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

Foamjet T two-component injection solution A+B 20+24 kg

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

FOX PURMAX FS601 WHITE 25

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

FOX ULTRASEAL-UV FS485 white SET 30kg

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

FOX BASEMOR FC205 GRAY 25 kg - mortar

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

PVC membrane MAPEPLAN M 15 BROFF T1/T3 2.10x20

- category: Waterproofing / Membranes

- Brands: MAPEI

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

WEBER DRY SS 10 20 KG (waterproofing powder)

- category: Coating waterproofing

- Brands: WEBER

Two-component polyurethane waterproofing COMPOSIT CRYSTAL (set)- 6.74KG

- category: Coating waterproofing

Primer bituminous (Primer) Profimast (5 l / 4.5 kg)

- category: Coating waterproofing

Polyurethane waterproofing Purtop Easy / 25 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

KEEP DRY 18KG BIANCO OSTUNI - Liquid Extra Strength Membrane

- category: Coating waterproofing

- Brands: ICOBIT

FOX CERAFLEX FX114 GREY 25 kg - High-strength cement adhesive

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

Planitop Rasa e Ripara - fibre cement for levelling concrete surfaces and repair work

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

Hydrostekloizol TPP 3.5 (1*10m2) )

- category: Waterproofing / Roll waterproofing

- Brands: KRZ

Synthetic rubber waterproofing Aquaflex Roof HR / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

Foamjet T two-component injection solution A+B 20+24 kg

- category: Waterproofing / Coating waterproofing

- Brands: MAPEI

FOX PURMAX FS601 WHITE 25

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

FOX ULTRASEAL-UV FS485 white SET 30kg

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

FOX BASEMOR FC205 GRAY 25 kg - mortar

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

PVC membrane MAPEPLAN M 15 BROFF T1/T3 2.10x20

- category: Waterproofing / Membranes

- Brands: MAPEI

Bitumen waterproofing Plastimul / 20 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

WEBER DRY SS 10 20 KG (waterproofing powder)

- category: Coating waterproofing

- Brands: WEBER

Two-component polyurethane waterproofing COMPOSIT CRYSTAL (set)- 6.74KG

- category: Coating waterproofing

Primer bituminous (Primer) Profimast (5 l / 4.5 kg)

- category: Coating waterproofing

Polyurethane waterproofing Purtop Easy / 25 kg

- category: Coating waterproofing / Waterproofing

- Brands: MAPEI

KEEP DRY 18KG BIANCO OSTUNI - Liquid Extra Strength Membrane

- category: Coating waterproofing

- Brands: ICOBIT

FOX CERAFLEX FX114 GREY 25 kg - High-strength cement adhesive

- category: Waterproofing / Coating waterproofing

- Brands: FOX BAU

delivery

- When purchasing products for up to 100 GEL, the delivery price is 6 GEL;

- When purchasing products in the amount of 100 to 500 GEL, the delivery price is determined on the basis of: 1 km - 1.50 GEL;

- When purchasing products worth more than GEL 300, delivery is free (Tbilisi);

- The cost of delivery outside the city is determined at the rate: 1 km - 2 GEL.

Delivery time:

- Tbilisi | Rustavi | Mtskheta | Kutaisi | Batumi

Delivery time: 3-5 working days

- Out of town:

Delivery time: 4-5 working days

Note: Delivery is carried out only to the address, without unloading from the car and delivery to the apartment.

Product comparison

POLYSINT grey kg.20

choose a product

- ANTIRADICE PE P 4mm F F 10m

- Planitop Rasa e Ripara - fibre cement for levelling concrete surfaces and repair work

- Hydrostekloizol TPP 3.5 (1*10m2) )

- Synthetic rubber waterproofing Aquaflex Roof HR / 20 kg

- MAPEPLAN EXTERNAL WAVY CORNER PLUS

- Foamjet T two-component injection solution A+B 20+24 kg

- FOX EPOMORTAR FC510

- FOX PURMAX FS601 WHITE 25

- FOX ULTRASEAL-UV FS485 white SET 30kg

- Bitumen waterproofing Plastimul / 20 kg

- PVC membrane Mapeplan D15 (1x20)

- FOX BASEMOR FC205 GRAY 25 kg - mortar

- FOX ULTRATEX

- PVC membrane MAPEPLAN M 15 BROFF T1/T3 2.10x20

- Icoforce 20 кг

- WEBER REP MA200 25KG

- BUTA Waterproofing Mastic (Rubber Based) 18L

- Bitumen waterproofing Plastimul / 20 kg

- WEBER DRY SS 10 20 KG (waterproofing powder)

- Two-component polyurethane waterproofing COMPOSIT CRYSTAL (set)- 6.74KG

- FOX WATERPROF FS100 18kg

- Xpro - hermetic - 0.5-5-10 KG

- Primer bituminous (Primer) Profimast (5 l / 4.5 kg)

- Polyurethane waterproofing Purtop Easy / 25 kg

- icoproof

- Idrostop Multi ST – injection packer

- KEEP DRY 18KG BIANCO OSTUNI - Liquid Extra Strength Membrane

- Primer bituminous Profimast (21.5 l / 16 kg)

- Waterproofing material R-COMPOSIT 10 KG

- FOX CERAFLEX FX114 GREY 25 kg - High-strength cement adhesive

POLYSINT is a ready product and must be stirred to an even, fluid consistency before being applied, using a brush, roller or airless spray gun.

Before applying POLYSINT, make sure you remove any parts that are loose, crumbling away or unsound, along with any paint, rust, dust or form oils; surfaces must be thoroughly

cleaned, sound and dry.

You are advised against applying POLYSINT if it is about to rain, or if there is a chance of dew, fog or frost as the product could get washed off or not adhere to the treated surface.

Avoid temperature extremes during the film's application and drying time.

You must be sure that there will be optimal installation conditions for at least 24 hours prior to and following application.

Being a water-based product, POLYSINT is affected by freezing temperatures and must be applied with ambient temperatures in the +5 to +35 °C range.

POLYSINT is applied in 2 coats: the second coat must be applied at least 24 hours after the first coat has been allowed to dry.

In the event you wish to improve the product's mechanical strength, or where it is not being applied straight on top of prefabricated bitumen membranes, we recommend applying

POLIESTERE 60 reinforcement.

To apply the reinforcement correctly, embed POLIESTERE 60 in the first coat while the material is still wet, applying suitable pressure as you roll over it so that it is incorporated

into the coating.

The average consumption rate varies depending on the substrate and desired thickness. Whatever the case, the average consumption rate for the 2 coats without reinforcement

is 1-1,5 kg/m2; while with reinforcement, it is 1,5-2 kg/m2.

The substrate should not be too hot as this accelerates the film-forming process, running the risk of the product not adhering properly and losing cohesion.

Do not apply to bitumen membranes that have just been installed as the natural small amount of migration of oils in the compound might mean the product fails to adhere

perfectly.

We recommend waiting at least 6 months when dealing with torched-on bitumen membranes or other bituminous materials, and 3 months on cold-applied bituminous materials;

in all cases, give the surfaces to be treated time to oxidize.